INTRODUCTION TO ROBOTICS TECHNOLOGY (Part 1)

Robotics technology consists of the devices, components, designs, and programming that have gone into development of robots as we

know them today. A large sector is

industrial robotics, with many of the industrial robots being essentially a

robotic arm. Read on for images and details about robots.

What is Robotics Technology?

Robotics

technology has developed considerably since the author, Isaac Asimov, coined

the term robotics in the early 1940's in one of his science fiction stories.

Robotics is defined as: The science or study of the technology associated with

the design, fabrication, theory, and application of robots, in the 2009 update

of the Fourth Edition of The American Heritage Dictionary of the English

Language. This definition brings up the question, 'What is a robot?' There are

indeed a number of definitions in use for 'robot.' A usable one that is

attributed to the Robotics Institute of America (RIA) is: A robot is a

reprogrammable multi-functional manipulator designed to move materials, parts,

tools, or specialized devices through variable programmed motions for the

performance of a variety of tasks.

What do Robots Do?

Industrial robotics (Materials

Handling)

In order

to learn about robotics technology, it is helpful to learn a bit about robots

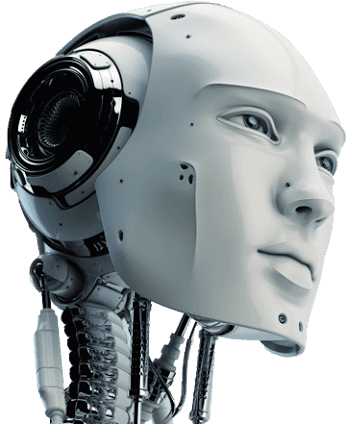

and their capabilities. When the idea of robots was first developing, they were

envisioned as humanlike in appearance and in behavior.

In order

to learn about robotics technology, it is helpful to learn a bit about robots

and their capabilities. When the idea of robots was first developing, they were

envisioned as humanlike in appearance and in behavior.

Industrial Robotics Welder

The

greatest number of robots in use, however, are industrial robots, which do not

look at all like humans. The images in this section show a couple of industrial

robots, one doing material handling and the other doing welding. Many

industrial robots, like the two shown here, look somewhat like an arm, and also

go by the name 'robotic arm.'

Unimate, the First Industrial

Robot

A large

percentage of the robots in the world are industrial robots used in a wide

variety of industries. Robots can do jobs that would be boring for humans and

jobs that are dangerous or dirty. Robotics technology has developed to the

point that robots can lift heavy objects, do precise assembly line work, pick

something up and place it precisely where it needs to be, guide a machining

operation, defuse bombs, or inspect sewers, just as a few examples.

The first industrial robot, Unimate, was

developed by George Devol, and was used for die casting handling and spot

welding by General Motors. This was perhaps a predictor of things to come,

because the automobile industry today is the largest user of industrial robots

and robotic arms.

In

addition to industrial robotics, another large sector is robot toys and

robotics in games. Robots in this sector are more likely to have an appearance

that is more like humans, and to have motion capabilities and the capability to

do human types of activities.

The Components of Robots

One way

of generalizing the nature of robotics technology is to categorize the typical

components of robots. The components of a robot would typically include a power

source, a means of sensing, actuators, a power source, a means of manipulation,

an overall structure, and perhaps a means of locomotion. Robotics sensors are

available to measure a wide range of parameters, such as light, temperature,

sound, or acceleration. Actuators make robots or parts of robots move. The most

commonly used actuator for robots is the electric motor. Batteries are a

commonly used power source. A couple of ways that manipulation can be

accomplished are with vacuum grippers or with mechanical grippers. Mechanical

grippers are the most common means of manipulation. The first robots used as industrial

robots were stationary and so didn't need any means of locomotion. Now robotics

technology has advanced so that some robots require a means of locomotion to do

the tasks for which they are designed. The simplest means of locomotion is four

wheels, although some robots move by a number of different methods, including

walking, snaking, or hopping.

Summary

Robotics

technology goes back at most 70 years, to the time when Isaac Asimov first used

the term robotics in his writing. The use of industrial robots, such as robotic

arms, has grown tremendously, so that now industrial robots carry out a wide

variety of tasks that are too boring, too dirty, or too dangerous for humans to

do.

ADVANTAGES OF ROBOTICS IN ENGINEERING

Some

advantages of robotics, like improved quality and quantity of production, are

due to the mechanical nature and computerized control in industrial robotics

technology. Other advantages of robotics are due to freedom from human

characteristics like boredom and the ability to do dangerous tasks.

Background

The

advantages of robotics have become more apparent as industrial robotics

technology has grown and developed in the 50+ years since the first industrial

robot, Unimate, was put into use in the 1950s. About 90% of the robots in use

today are in the industrial robotics sector in factories. As of 2004, about

140,000 industrial robots were in use in the U.S., as reported by the Robotics

Industry Association (RIA). Robots are now also used in warehouses,

laboratories, research and exploration sites, energy plants, hospitals, and

outer space.

The

advantages of robotics can be classified into four major categories: 1)

quality/accuracy/precision; 2) Efficiency/speed/production rate; 3) Ability to

work in environments that are unsafe or inhospitable for humans; 4) Freedom

from human limitations such as boredom and the need to eat and sleep.

Advantages of Robotics #1:

Quality/Accuracy/Precision

Unimate -

the First Industrial Robot

Many

industrial robots are in the form of a robotic arm. The image at the left shows

Unimate, the first industrial robot, which has the appearance of a robotic arm.

The image in the next section shows a contemporary industrial robotics arm. Due

to its mechanical nature and computerized control, a robotic arm can carry out

a repetitive task with great precision and accuracy, thus providing improved,

consistent product quality. This would apply to quite a variety of production

line tasks, like welding, assembling a product, spray painting, or cutting and

finishing.

Advantages of Robotics #2:

Efficiency/Speed/Production Rate

The same

features of industrial robotics technology mentioned above, the mechanical

nature of the equipment and the computerized control, make industrial robotics

technology more efficient and speedy, leading to higher production rates than

with human labor. Another aspect of efficiency is that robots can be mounted

from the ceiling and have no problem with working upside down. This can lead to

a savings in floor space.

Advantages of Robotics #3: Ability

to Work in Environments that are Inhospitable to Humans

This is

an interesting set of advantages of robotics. There are a number of tasks that

are too dangerous, too exposed to toxins, or just plain too dirty for humans to

conveniently do them. These are ideal robotics tasks. This includes tasks as

simple as spray painting, because there is no need to worry about the robot

inhaling the paint fumes! It also includes such daunting tasks as defusing

bombs and such dirty tasks as cleaning sewers.

Advantages of Robotics #4:

Freedom from Human Limitations like Boredom

This set

of advantages of robotics is due to the fact that human characteristics like

boredom from doing a repetitive task don't interfere with the functioning of a

robot. There is some overlap with the first two categories of advantages of

robotics, because the lack of interference from boredom leads to greater

accuracy, quality, and rate of production. There is more to this set of

advantages of robotics, however. Since a robot doesn't need to rest or eat, and

never gets sick, a robotic arm can work 24/7, with only limited occasional

downtime for scheduled maintenance.

An

article about the advantages of robotics wouldn't be complete without some

discussion of the limitations of robotics. In spite of the very useful set of

advantages of robotics discussed above, there are some tasks for which human

beings are better suited than robots. For example:

○ Robots are not suited for creativity or

innovation

○ Robots are not capable of independent

thinking

○ Robots are not good at learning from

their mistakes

○ Robots are not as suitable for making

complicated decisions

○ Robots can't as readily adapt quickly to

changes in the surroundings

Human beings

are needed for these types of tasks, so there is hope that we will not become

superfluous in a world dominated by robots at some point in the future, as

projected by some science fiction authors!

Comments

Post a Comment